Grounding Contact Test

Grounding receptacles having a 5-15R,5-20R,6-15R,6-20R,7-15R,14-15R or 15-15R configuration are to be subjected to the tests in this section.

Previously untested devices are to be used. Each device is to be mounted in a flush device box, or as otherwise intended, with its face in a vertical plane. A nonmetallic faceplate is to be installed if intended. A solid 14 AWG (2.1 mm2) copper conductor is to be connected to the receptacle grounding terminal.

With the receptacle oriented to create the maximum contact displacement (possible distortion of contact affecting its contact ability), the test pin A,Figure 125.1 is to be fully inserted in the grounding contact. A 5 lb (2.27 kg) weight is to be gradually suspended form the test pin 6 inches (152 mm) from the face of the receptacle. The weight is to be applied for 1 minute, following which, the weight is to be removed. The application of the weight is to be repeated with the receptacles rotated 90, 180 and 270 degrees for a total of four applications. Usually the test is started with the grounding pin opening directly above, below or on either side of the line slots.

As a result of the test described in 125.3, there shall not be any breakage of the outlet face of the receptacle that would expose live parts to contact by 1/16 inch (1.6 mm) diameter rod. In addition, there shall not be any breakage or distortion of the insulating body of the receptacle that results in reduction of electrical spacings to values less than those required for the receptacle. The conditioning pin shall remain in place without extraneous support for the required 1 minute in each position.

Exception: If breakage occurs at the base of the grounding contact opening in a controlled manner so that the breakage is clean and does not expose live parts or break internal bariers, minimal extraneous upport of the conditioning pin is not prohibited to complete the stress conditioning on the grounding contacts.

Each device is then to be tested for electrical continuity between the receptacle grounding contact and the fully inserted test pin B, Figure 125.2. There shall not be a loss of contact while the pin is moved by hand, without exerting undue pressure, so as to touch all internal walls and surfaces. The stop ring of the pin is to remain continuously in contact with the face of the receptacle. An indicating device, such as an ohmmeter, a battery-and-buzzer combination, or other similar device, is to be used.

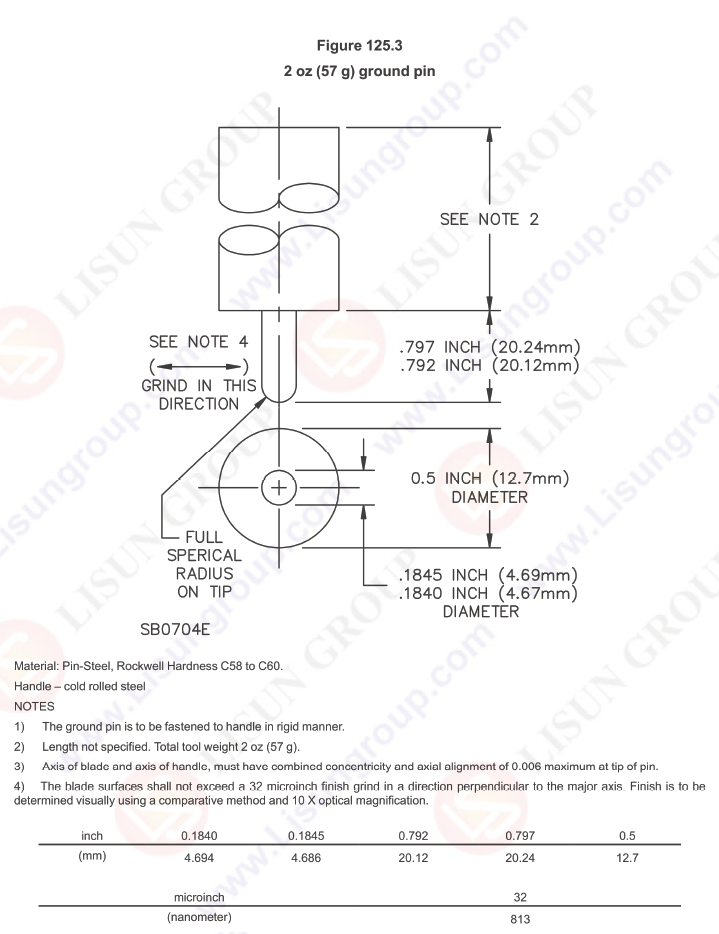

Each device is then to be positioned with the receptacle outlet facing down in a horizontal position. The receptacle shall support the 2 and 4 oz. (57 and 113 g) grounding pin illustrated in Figure 125.3 and Figure 125.4, for 1 minute each when fully inserted in the grounding pin opening.

With Standard UL 498 Figure 125.3 Grounding Pin

isun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

https://www.lisungroup.com/news/technology-news/with-standard-ul-498-figure-125-3-grounding-pin.html

.jpg)

.jpg)

Comments

Post a Comment